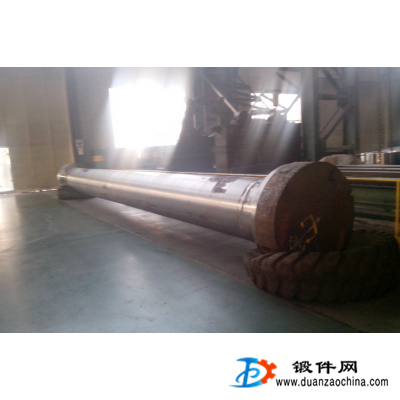

大型水轮机轴 turbine shaft 水电主轴

Heat Treatment Heavy Forged Steel Shaft Hydropower Spindle

Description:

The forged steel shaft-hydropower spindle forging is widely used for large scale hydropower equipment industry. For example: Alstom, Voith Siemens Hydro Power Generaion, Ha’erbin Hydropower group, Toshiba Hydro power and so on. The products conform to Standard of ASTM A668/A668-96 and JB/T1270-2002.

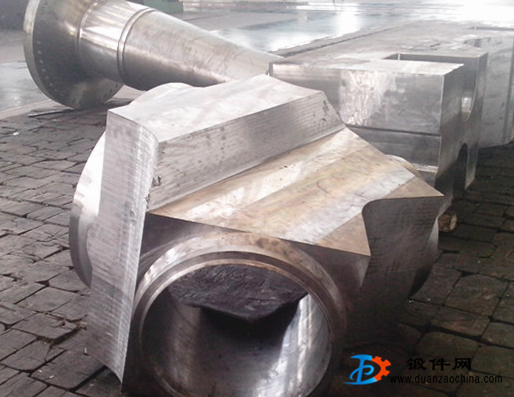

The manufacturing equipment is 30~185MN hydraulic press, the forging ratio >4.5, the technical condition is in accordance with the standard of ASTM A668/A668-96 and JB/T1270-2002.

The product can be provided as per your drawing or specified requirements.

Smelting Process:EF+LF + VD

The process as follow :Ingot →heat → forging → Heat treatment (Normalizing+ tempering) → Inspection →rough machining→UT →finishing machining →Inspection

Applications: The forged steel shaft-hydropower spindle forging is widely used for large scale hydropower equipment industry.

Specifications:

|

Description |

Forged steel shaft- hydropower spindle forging |

|

material |

Alloy steel (20SiMn etc.) |

|

Material standard |

ASTM or GB/T3077-1999 |

|

Dimension |

Max.OD of flange: 2000mm Max. Length: 15000mm |

|

Weight |

Max. 250 ton |

|

Smelting Process: |

EF+LF + VD |

|

Process |

Ingot→heat → forging → Heat treatment (Normalizing+ tempering) → Inspection →rough machining →UT →finishing machining →Inspection |

|

UT standard |

ASTM A388 or EN10228 |

Competitive Advantage:

Quality control and management to the whole produce process, including ingot smelting, forging, heat treatment, machining and strictly final inspection prior to delivery.

Excellent product quality and service, competitive price, “in-time” delivery

通过认证

通过认证